Design,Prototype,Innovate,Manufacture.

From concept to mass production, GT&C turns ideas into reliable plastic components with precision moulding and 25+ years of engineering expertise.

Industries we serve

Automotive

Consumer

products

Electrical

Medical

Why Us?

25+ Years of Experience

Over two decades in injection moulding, handling everything from tiny high-precision parts to larger complex components across multiple materials, tolerances, and operating environments.

True One-Stop Manufacturing

From tool design and insert manufacturing to moulding, tool maintenance, and quick repairs—everything is handled in-house to keep your production running without delays.

High-Precision Capability

Specialized in small, tight-tolerance parts and insert moulding, where consistency and accuracy matter the most.

Dedicated Quality Control

In-house quality personnel ensure every batch meets defined specifications and customer requirements.

Fast Tool Support & Maintenance

Immediate in-house tool servicing minimizes downtime and prevents costly production interruptions.

Engineering-Driven Approach

We don’t just mould parts—we help optimize designs for manufacturability, cost, and long-term performance.

Strategic Industrial Location

Located in Peenya, Bangalore—close to major industrial hubs, Yeshwanthpur railway station, and within easy reach of Kempegowda International Airport for audits and visits.

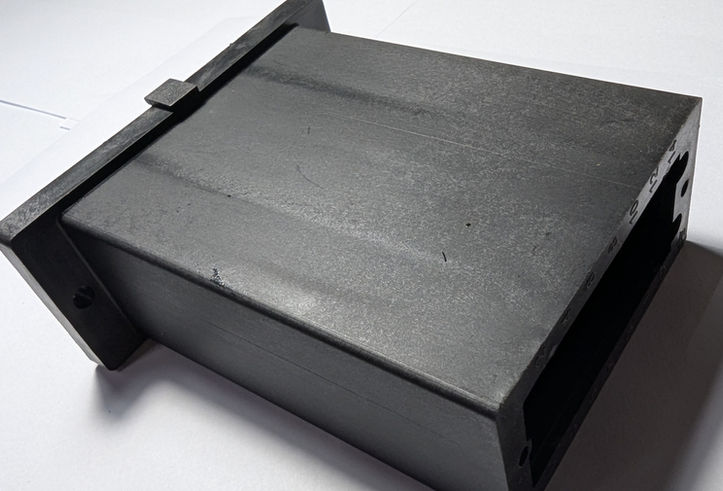

Gallery

Our Services

Injection Moulding & Mold making:

Helvetica Light is an easy-to-read font, with tall and narrow letters, that works well on almost every site.

Injection Moulding

Injection moulding is our core capability. We manufacture high-precision plastic components with consistent quality, tight tolerances, and repeatable production.

Overmoulding & Insert Moulding

We provide overmoulding and metal or plastic insert moulding to enhance part strength, functionality, and assembly efficiency in complex components.

Injection Mould Tooling

We design and manufacture durable, production-ready injection mould tools optimized for accuracy, longevity, and efficient cycle times.

Insert-Only Plastic Mould Tools

To reduce upfront tooling investment, we offer insert-only mould tooling using standard bolsters. This approach is ideal for cost-sensitive or low-risk production programs.

Secondary Processes:

Helvetica Light is an easy-to-read font, with tall and narrow letters, that works well on almost every site.

Pad Printing

Our pad printing service enables precise printing on complex plastic moulded surfaces for logos, markings, symbols, and identification text.

Ultrasonic Welding

We offer ultrasonic welding for clean, strong, and repeatable bonding of plastic components without adhesives or mechanical fasteners.

Secondary Machining

We perform machining operations to achieve critical tolerances, functional features, or finishing requirements beyond the moulding process.

Assembly & Engineering Support:

Helvetica Light is an easy-to-read font, with tall and narrow letters, that works well on almost every site.

Electrical & Mechanical Assembly

We streamline your production by delivering fully integrated sub-assemblies. By combining precision plastic moldings with electrical and mechanical components, we eliminate your extra handling steps and slash assembly time

Reverse Engineering

Our reverse engineering service analyzes existing components to recreate accurate designs and tooling-ready data for reliable reproduction.

Metal to Plastic Conversion

We help convert metal components into engineered plastic alternatives that reduce weight and cost while maintaining required strength, performance, and functionality.

In-House Insert Manufacturing:

Helvetica Light is an easy-to-read font, with tall and narrow letters, that works well on almost every site.

Insert Manufacturing

We manufacture custom metal and alloy inserts—including threaded inserts, pins, bushings, and plates—designed for seamless integration into plastic moulded components.

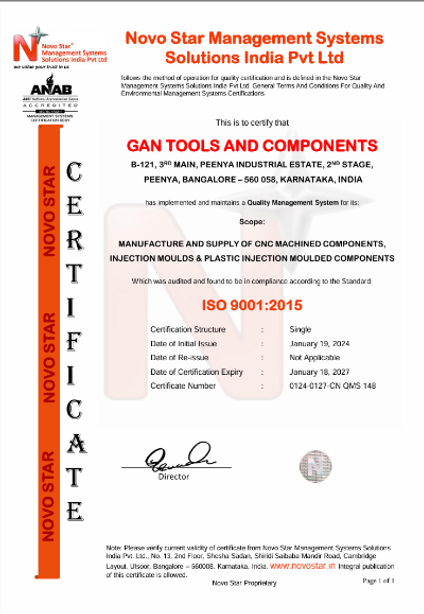

Certifications

ISO 9001 Certification

Clients